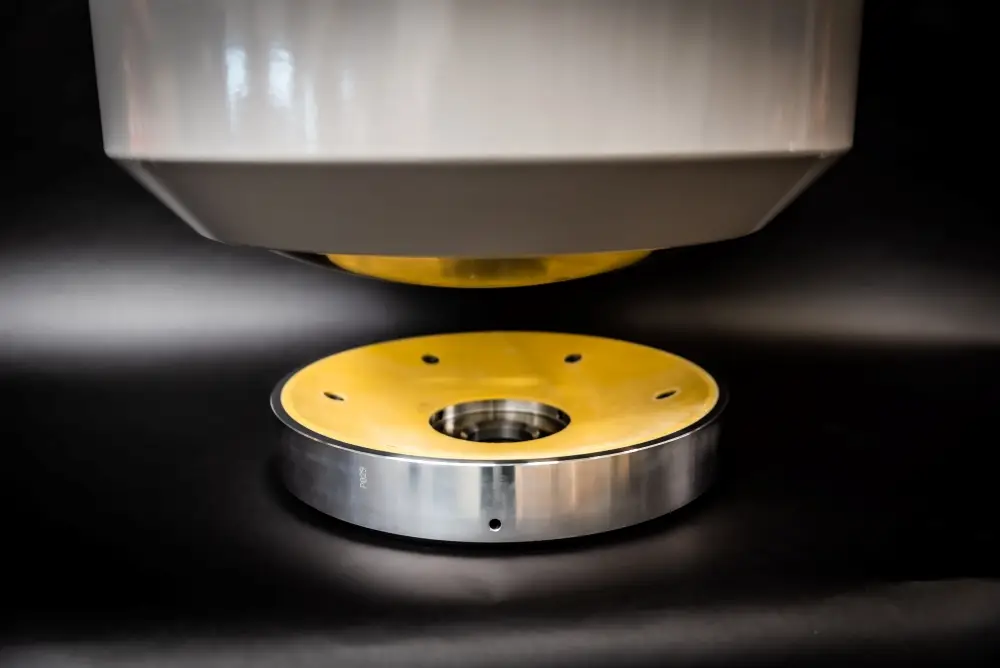

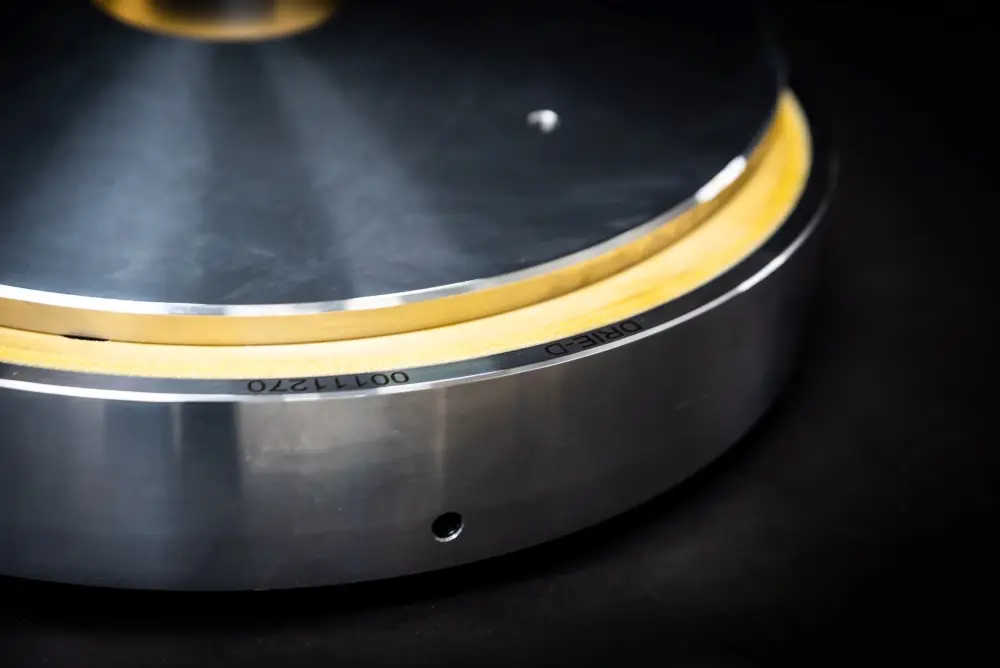

Self-lubricating bearings

Composite plain bearings

Are you looking for a self-lubricating bearing? DRIE-D specializes in the design and production of a wide range of self-lubricating composite plain bearings for numerous applications all over the world.

Our bushings, thrust washers, wear plates and spherical bearings are used in many high-demand applications. Several production companies rely on our self-lubricating D-glide® materials for the smooth movement of their products. Whether it concerns custom-made bearings or serial production, DRIE-D gives your product the attention it deserves.

The downside of lubrication

By far the most important reason for lubrication is to obtain optimal sliding properties. Besides that, lubrication also ensures that the counter-face material is protected against corrosion. Before the advent of composite plain bearings, the use of bronze bearings in combination with a (automatic) lubrication system was common practise. The downside of this combination, however, is that you are completely dependent on the correct functioning of the lubrication system. If for any reason this fails or no longer functions properly, the bearing will no longer get the necessary lubrication and will fail.

Another major disadvantage of lubrication is the fact that it attracts contamination and over time can act as an abrasive paste instead of a lubricant. This will cause higher friction values and increases wear significantly. To prevent this, a continuous and accurate lubrication regime is necessary. Imagine eliminating those maintenance schedules and costs, just by using material that gets the lubrication out of its own material.

Advantages of self-lubricating composite bearings

With the use of self-lubricating composite bearings, you will have the best of both worlds. Our D-glide® bearings acquires the lubrication out of its own material, which always gives you the best possible sliding properties. On the other hand, self-lubricating bearings will eliminate the need for regular maintenance, reducing downtime and labor costs associated with manual lubrication.

Compared to conventional metallic bearings, composite bearings are more elastic. This means they offer more design flexibility and are better at absorbing small deformations, such as shaft misalignment. As a result, the load is more evenly distributed over the support surface, reducing the maximum Hertzian stresses in the material. This will significantly extend the life time of the bearings and reduce the chance of damage to the counter-face material. This is a key advantage of using composite bearings over metallic bearings in specific applications.

Self-lubricating composite bearings

In addition to the self-lubricity of D-glide®, our material has many other advantages, such as:

- Wear resistant

- High load capacity

- Self-lubricating

- High chemical resistance

- Negligible water absorption

- Low sensitivity for stick-slip

- Maintenance-free

Applications with self-lubricating bearings

- Bridges

- Cranes

- Sluices

- Vertical pumps

- Cutter suction dredgers

- Spud carrier guides

- Back hoe

- Monopile grippers

- Monopile upending tools

- Mooring systems

- Skidding systems

- Fairleads

- FPSO turret bearings

- Sheave bearings

- Turning glands

- Bogie bearings

- Slewing bearings

- Hinge bearings

- Transition piece guides

- Rod end bearings

- Hydraulic cylinder bearings

Mark Erkens

Lead Engineer

If you require technical input on your mechanical motion challenge, our Lead Engineer Mark is available to assist you.

Patrick Overmeer

Product Manager

If you require a quotation or have a product-related inquiry, our Product Manager Patrick is available to assist you.

Request the material data sheets

Fill out the contact form below to request our material data sheets. You can also indicate if you would like to get in touch with our engineering department or if you have an inquiry for which you would like to receive a proposal.

Your contact details will only be used to contact you about this request and will not be used for unsolicited sales calls.