Bearing Technology

Custom-made solutions

Setting new standards in solutions for everything that needs to rotate or slide (or a combination of both). DRIE-D is specialized in designing bearings for any application in demanding markets like offshore, dredging, civil structures, handling and mission equipment, taking advantage of our D-glide® composite.

D-glide® bearings allow higher loads than virtually all other plain bearings and have less friction and less wear. To create the best possible bearing designs, it is essential that all the right choices are made. To meet this purpose, DRIE-D has put together a team of dedicated and experienced engineers. Whether it concerns custom-made bearings or serial production, DRIE-D gives your product the attention it deserves.

D-glide® composite

Serial production

In addition to designing bearing solutions for complex applications, we can also think along in the most cost-efficient design and production of bearings for serial production. Because we are not bound to standard dimensions, a custom-made product that exactly matches your needs can be supplied for every application. We already serve a wide range of respected customers, with smaller series of 20 pieces up to thousands of pieces per year.

We are also familiar with framework contracts with which a competitive price level, minimum stock and short lead times can be arranged according to customers requirements.

By involving our engineers early in your design process, you gain insights and solutions that improve cost-effectiveness and shorten production timelines. With more than 25 years of experience and expertise in various quality and inspection procedures, you will receive thorough support and compliance at every stage of your project. Trust DRIE-D for reliable and cost-effective series production that meets your exact requirements.

If you need a specific bearing in serial? Contact us for more information.

Design & Engineering

Our dedicated engineers work in teams together with our customers to create the best possible solution. Pure specialists thriving on the challenges of modern world engineering.

We can design and engineer solutions for your mechanical motion challenge, or one of our engineers can join your team to integrate the use of sustainable D-glide® in your bearing solution.

Are you also interested in a new and cooperative approach, to jointly find the best, most durable and reliable bearing solution for your mechanical motion challenge? We are more than willing to share our expertise and to help you make the right choices for your bearing design.

Sustainable & Innovation

The use of D-glide® eliminates the need for lubrication. This results in sustainable bearings that can be deployed in any type of environment without risk on pollution by lubricant. For the production of D-glide® no hazardous substances are used, making the material itself sustainable as well. A third advantage follows from a different and innovative design approach. This approach often allows for more compact designs, including additional advantages or redundancy built into the bearing system.

Involvement of our bearing specialists from the conceptual phase of your engineering project gives optimal opportunity to explore progressive design possibilities and include as many innovative advantages in both the bearing itself but also in the surrounding construction.

Quality assurance & Project management

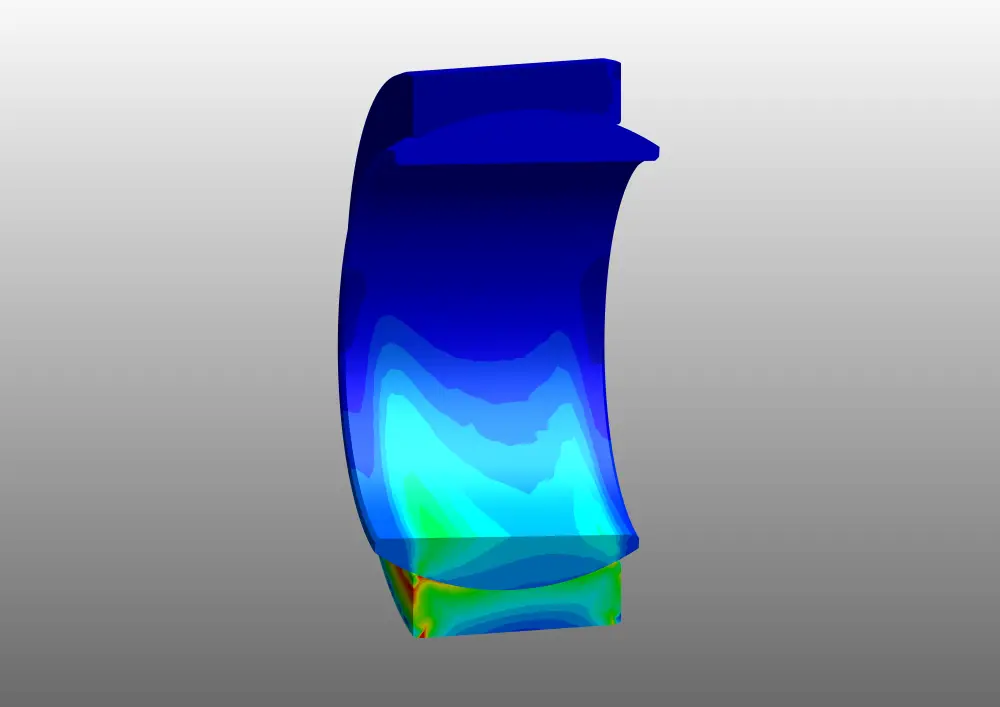

Finite Element Analysis & Heat calculations

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.