Self-lubricating bearings in agricultural environment

Withstanding rough agricultural environments

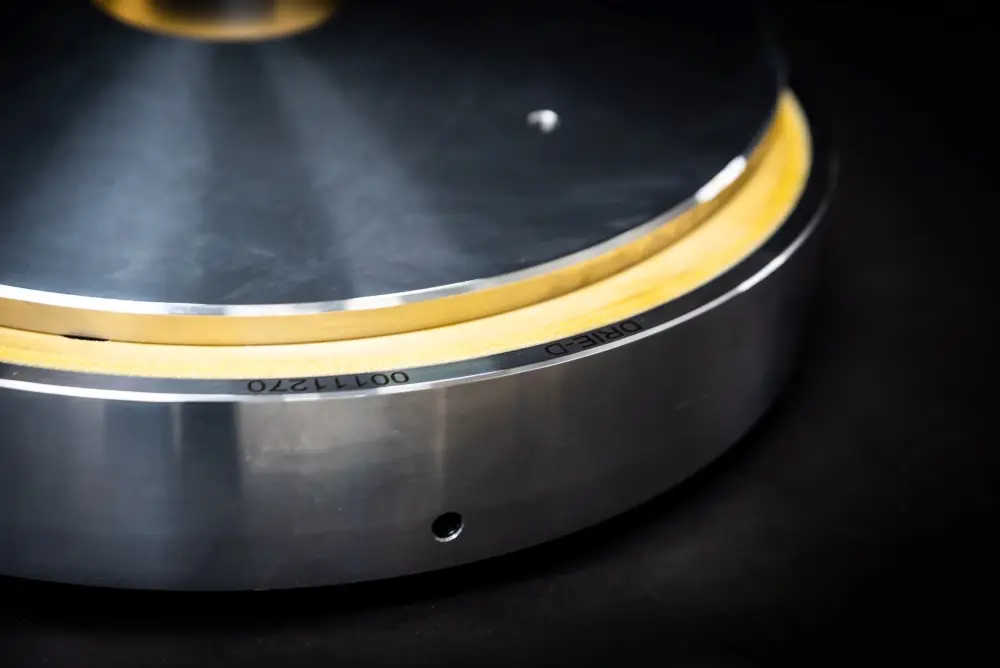

In agriculture, machinery often works in tough conditions with lots of mud and dust. Keeping this equipment running smoothly is essential, but traditional lubrication systems can cause issues, leading to more maintenance and unexpected breakdowns. From seeders and harvesters to transport equipment and soil cultivation machines, our bushings, thrust washers, wear plates, and spherical bearings are designed to ensure smooth and reliable operation. Our self-lubricating D-glide® materials are ideal for demanding agricultural applications, offering exceptional performance in abrasive environments.

The downside of traditional bearings with lubrication

Agricultural machinery bearings require optimum sliding properties, high load capacity and a reliable lifetime. These are challenging goals given the environment in which the equipment operates. Traditionally, bronze and metal bearings with lubrication systems were used to ensure smooth operation and protection against corrosion. Without an automatic lubrication system, reliable operation of the equipment comes down to the discipline of the operator to lubricate periodically.

If an automatic lubrication system fails, the bearing can wear out quickly, leading to potential failure and unexpected downtime. Repairing or replacing this bearing, which is often installed in hard-to-reach locations inside machinery, is not desirable. Besides the unexpected downtime, keep in mind that lubrication attracts and encapsulates dirt which will turn the grease into a sticky abrasive paste over time. Although adding more lubrication seems like a solution it often leads to a recurring cycle of problems.

The advantages of self-lubricating composite bearings

Fortunately, time has not stood still and nowadays there are good alternatives for traditional bearings.

D-glide® bearings are designed to provide optimal sliding properties by gaining lubrication from the material itself. This means that you have the benefits of an automatic lubrication system, but then without the disadvantages of unexpected failure. Another benefit of composite compared with conventional metallic bearings is the elasticity of the material. This means they offer more design flexibility and are better at absorbing small deformations, such as shaft misalignment. As a result, the load is more evenly distributed over the support surface, reducing the maximum Hertzian stresses in the material. This will significantly extend the lifetime of the bearings and reduce the chance of damage to the counter-face material. This is a key advantage of using composite bearings over metallic bearings in agricultural applications.

Self-lubricating composite bearings

In addition to the self-lubricity of D-glide®, our material has many other advantages, such as:

- Wear resistant

- High load capacity

- Self-lubricating

- High chemical resistance

- Negligible water absorption

- Low sensitivity for stick-slip

- Maintenance-free

Application of self-lubricating bearings in the agricultural sector

- Soil cultivation equipment

- Harvesting equipment

- Hay and forage equipment

- Milking robot

- Seeding equipment

- Sprayer and applicators

- Transport equipment

- Plows

- Front loaders

- Planting equipment

- Feeders

- Bulldozers

- Cranes

- Graders

- Skid steer loaders

- Pile drivers

- Hydraulic cylinders

Mark Erkens

Lead Engineer

If you require technical input on your mechanical motion challenge, our Lead Engineer Mark is available to assist you.

Patrick Overmeer

Product Manager

If you require a quotation or have a product-related inquiry, our Product Manager Patrick is available to assist you.

Request the material data sheets

Fill out the contact form below to request our material data sheets. You can also indicate if you would like to get in touch with our engineering department or if you have an inquiry for which you would like to receive a proposal.

Your contact details will only be used to contact you about this request and will not be used for unsolicited sales calls.