The Afsluitdijk

Protection of millions of people

The Afsluitdijk, a 32-kilometre-long dam completed in 1932, has been protecting the Dutch coastline from flooding for nearly a century. It shields hundreds of kilometres of vulnerable coast and millions of people from high tides and storm surges. After almost 90 years of service, the Afsluitdijk required modernization to meet the challenges of rising water levels, more frequent storms, and heavier rainfall. Key technical systems, such as discharge channels and sluices, were upgraded and expanded for greater capacity. Additionally, Europe’s largest pump station was built to ensure water discharge, even during high tides.

The challenge:maximize reliability and minimize maintenance

To ensure maximum reliability and minimize maintenance, all joints, hinges, guides, slides, and bearings were designed to be maintenance-free. DRIE-D joined the engineering team of the LEVVEL construction consortium to develop these maintenance-free solutions for the Afsluitdijk’s moving components. Every design was built on proven technology to guarantee reliability.

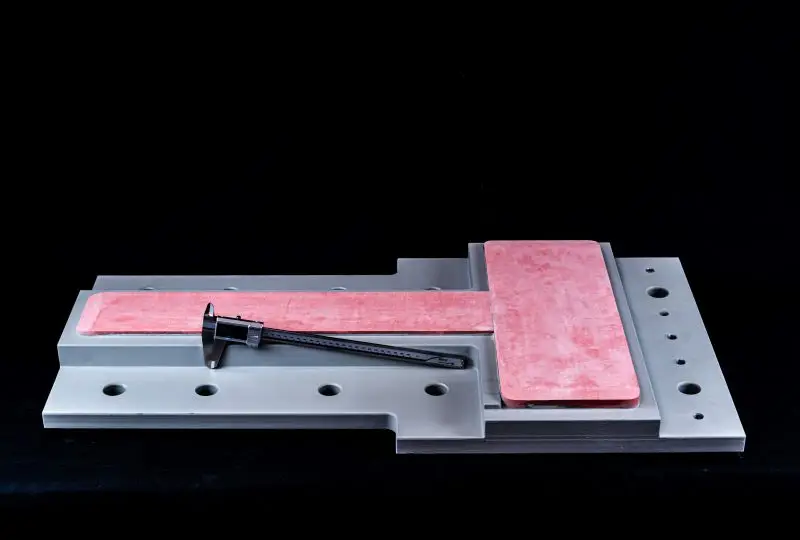

With a required lifespan of at least 25 years, meticulous attention was given to every detail, including material selection, counter face specifications, and corrosion protection for non-resistant components.

Friction-critical components were tested at the renowned Soete Institute in Ghent, Belgium.

The solution:Custom design supports with D-glide®

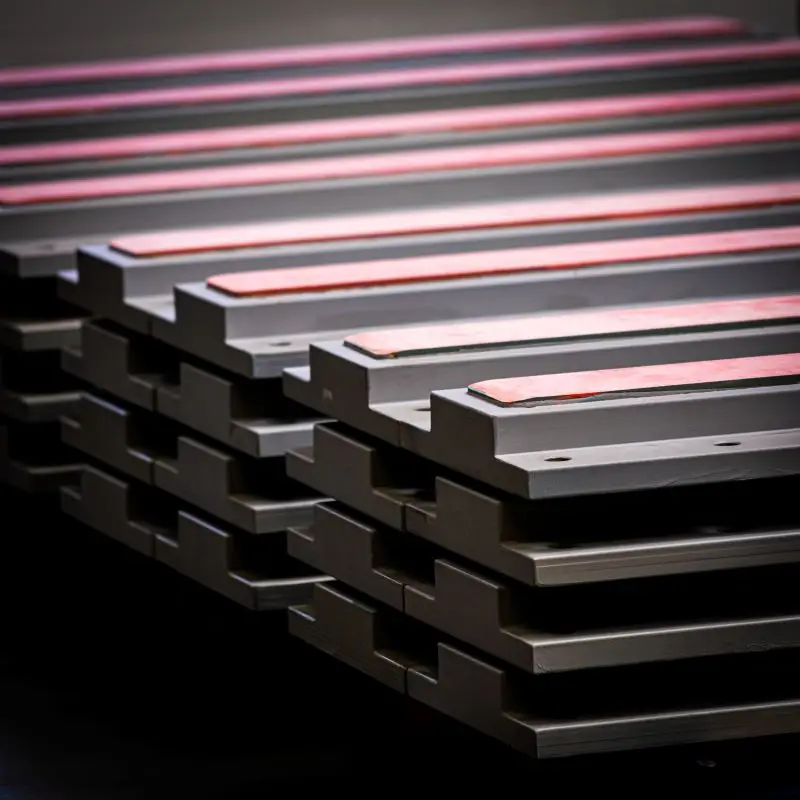

Intelligent bearing designs were essential to address the diverse challenges of upgrading the Afsluitdijk. For example, the gates of the discharge channels transitioned from traditional wheels to D-glide® sliders. With no moving parts, these sliders eliminate the risk of sudden failure and, with the right sliding rail, they are completely maintenance-free. Managing friction was critical, as excessive friction could prevent the gates from closing. Extensive testing, even with added sand and marine growth, confirmed that friction remained consistently below the required limits. The result is a simple, compact, fail-safe solution that ensures the gates close reliably in any condition.

The pumps are protected from seawater by check valves that open with water pressure when the pumps are in use. Since their operation is unpredictable, a design was created to handle both long periods of inactivity and intensive usage. These valves endure a range of conditions, from dry exposure to being submerged in seawater, yet they must perform consistently. To meet these demands, a bolt-on high-load hinge was developed, incorporating all the necessary functionality.

The sluice doors rotate on ultra-wear-resistant D-glide® bearings, powered by hydraulic cylinders with D-glide® spherical bearings and bushings in the cardanic joints. The composite gates of the fish migration river use D-glide® sliders for smooth operation, and the pink D-glide® guides of the safety lock gates are clearly visible when the gates are closed.