D-glide® F composite material

Engineered for dynamic applications

D-glide® F is our standard bearing material for all dynamic applications where strength, durability, and low friction are essential. It offers a high compressive strength combined with desired elasticity, enabling the bearing to absorb limited misalignments and deformations without getting damaged.

Thanks to its built-in solid lubrication, D-glide® F provides consistently smooth, maintenance-free operation without the need for oil or grease. Its negligible water absorption, outstanding chemical resistance and suitability for use in seawater make it an ideal choice for any onshore and offshore environment.

What makes D-glide® F unique?

D-glide® F is a high-performance composite material made from high-quality synthetic fibres, thermoset vinyl ester resin, solid lubricants, and carefully selected additives. This combination results in a material that is strong yet elastic, able to withstand high loads while absorbing stress, shock loads and limited misalignment. In addition, the material maintains its mechanical strength even at elevated temperatures and shows minimal creep over time.

The solid lubricant is embedded throughout the resin, ensuring low friction values and smooth sliding motion without the need for active lubrication. As a self-lubricating material, D-glide® F significantly reduces the need for maintenance in any imaginable application.

D-glide® F has negligible water absorption and excellent chemical resistance, making it ideally suited for use in virtually any environment, including continuous operation in seawater, without the need for sealing or special protective measures. As a non-metallic and electrically insulating material, it does not initiate or accelerate galvanic corrosion when in contact with metallic components. An additional benefit of its non-metallic nature is the elimination of fretting and galling during installation and dismantling, common issues with metal-on-metal interfaces. This simplifies assembly, reduces wear, and ensures a longer service life with minimal risk of damage.

Typical applications with D-glide® F

D-glide® F is designed for dynamic applications where bearings are exposed to continuous or frequent movement, high loads, and demanding environmental conditions, such as:

- Hinges, pivots, and sliding elements in offshore and marine structures

- Articulation points in mooring systems, motion compensation units, and offshore platforms

- Sliding plates and oscillating bearings in dredging and civil engineering projects

- Bearings in cranes, winches, and other heavy lifting equipment

- Pump, turbine, and hydraulic cylinder bearings operating in wet or submerged conditions

Thanks to its combination of strength, self-lubrication, and chemical resistance, D-glide® F offers a reliable, long-term solution where conventional materials such as steel or bronze would require frequent maintenance or replacement.

Design support

Designing with composite materials like D-glide® F requires a different approach compared to working with steel or bronze bearings. Factors such as surface pressure, alignment, thermal expansion, and heat dissipation play an important role in achieving optimal performance.

At DRIE-D, we have extensive experience in developing and optimising composite bearing solutions for demanding applications. Whether you are designing a new system or upgrading an existing bearing arrangement, we can help you select the right material and configuration for your needs.

Key benefits of D-glide® F

- High load capacity – suitable for heavy-duty and dynamic applications

- High elasticity – absorbs shock loads and tolerates misalignment

- Self-lubricating – no need for oil or grease

- Low friction – ensures smooth and consistent movement

- Low sensitivity to stick-slip – reliable performance even at low speeds

- Friendly to counterface materials – reduces wear on shafts or contact parts

- Negligible water absorption – suitable for submerged applications

- High chemical resistance – performs in harsh and corrosive environments

- Non-metallic and insulating – electrically insulating which prevents galvanic corrosion

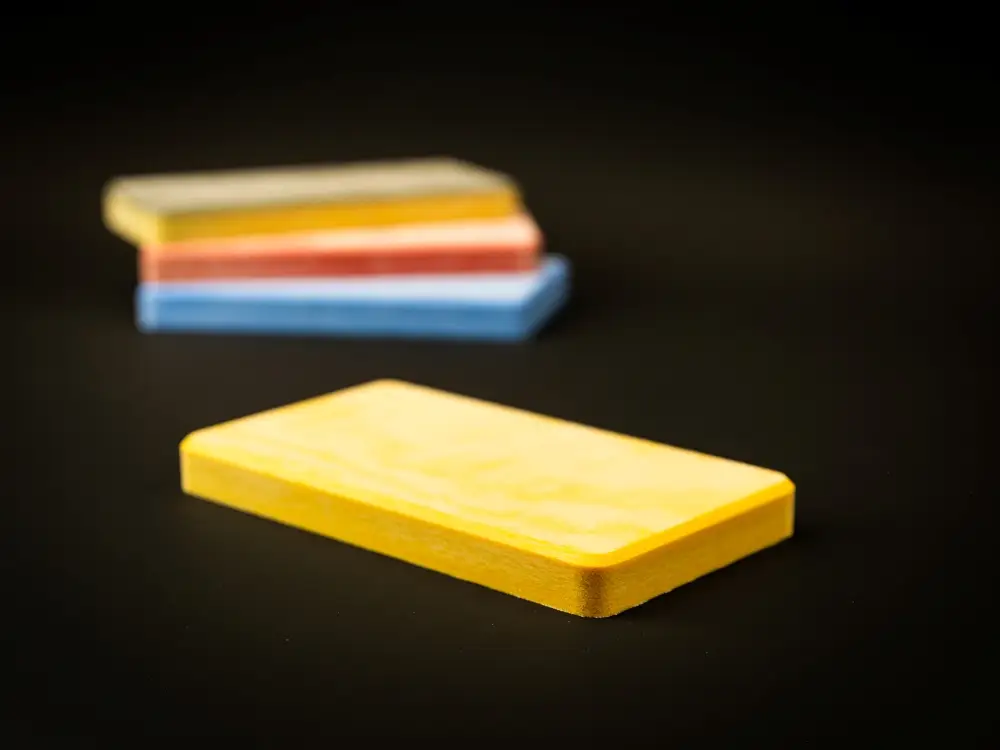

Our D-glide® grades

- D-glide® F is the standard grade for all dynamic applications and an excellent maintenance free alternative for traditional steel or (self-lubricating) bronze bearings.

- D-glide® FT has a special sliding layer, which is the clearly distinguishable greenish layer. D-glide® FT has the lowest possible friction with minimal difference between static and dynamic friction.

- D-glide® FC has additional additives in the resin that increase the abrasive wear resistance of the material by up to ten times compared to D-glide® F.

- D-glide® P is suitable for all semi-static applications and an excellent maintenance free alternative for traditional steel or (self-lubricating) bronze bearings.

Request our material data sheets

Fill out our contact form below to request the material data sheet of D-glide® F.

To schedule a brief online meeting with one of engineers, please click here.

Patrick Overmeer

Product Manager

If you require a quotation or have a product-related inquiry, our Product Manager Patrick is available to assist you.

Mark Erkens

Lead Engineer

If you require technical input on your mechanical motion challenge, our Lead Engineer Mark is available to assist you.

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.