Brake shoe for kalmar straddle carrier

High-quality replacements

Advanced manufacturing and quality assurance

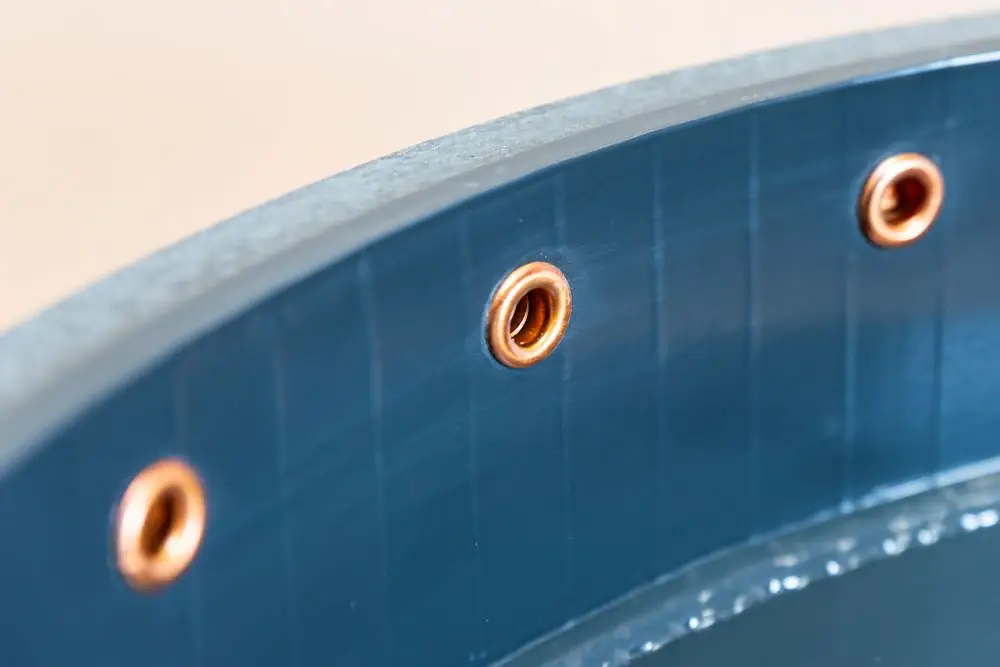

To meet this demand, we at DRIE-D have undertaken the production of these essential brake shoes for Kalmar Straddle Carriers. Utilizing state-of-the-art 3D scanning equipment and reverse engineering techniques, we have developed precise replicas of the original brake shoes. Our team of experts has ensured that these new brake shoes meet the highest standards of quality and performance, providing a reliable solution for maintaining older Kalmar straddle carriers.

Despite the age of these carriers, they continue to be used in various locations around the world, including Italy, Africa, and both North and South America. We have tailored our production to cater to these regions, ensuring that operators can keep their fleets running smoothly. Our brake shoes are sold as complete sets, as seen in our product photos, offering a convenient and cost-effective solution for our customers.

Additional products and OEM references

- OEM Brake Shoe 803601801

- OEM Brake Shoe 803601802

- OEM Brake Shoe 803601805

- OEM Brake Shoe 803601806

- OEM Brake Lining Set 12999601VT

Contact us about brake shoe for kalmar straddle carrier

Do you need any information about brake shoes for kalmar straddle carrier?

Contact our Friction Specialist Dave Habets by phone at +31 – 10 3134 720 or send an email.

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.