Brake Blocks Railway

Safe and reliable

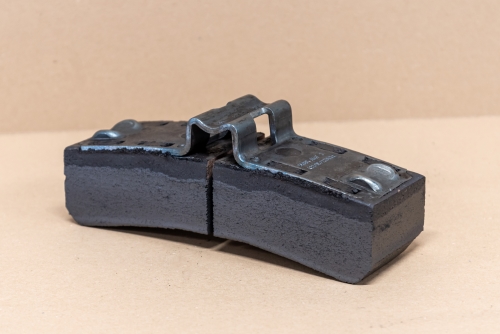

Railway brake blocks are critical components of any railway system, playing a vital role in ensuring the safety and reliability of trains. In this comprehensive guide, we will discuss everything you need to know about railway brake blocks, including their function, types, materials, and maintenance.

Jurid® products in our portfolio

- 816 M (sizes) 250 & 320

- 816 (sizes) 250 & 320

- J838 (sizes) 250 & 320

- J822 (sizes) 250 & 320

As European partner of Federal-Mogul, we deliver the Jurid® friction material for rail freight wagons. Jurid® brake blocks are suitable for a wide range of railway applications, including heavy-duty freight trains and high-speed passenger trains. Its high-temperature resistance, wear resistance, and has a low noise and dust production. These features combined makes It a highly reliable and cost-effective choice for railway operators.

Materials in railway brake blocks

The Jurid® brake blocks are made of a mixture of synthetic resins, metal fibres, and ceramic materials. The combination of these materials results in a highly durable and efficient brake block that is suitable for a wide range of railway applications.

One of the key benefits of Jurid® is its excellent performance in high-temperature environments. The synthetic resins and ceramic materials used in the brake block can withstand extreme temperatures, making them suitable for use in heavy-duty applications, such as freight trains. This high-temperature resistance also ensures that the brake blocks maintain their effectiveness, even under prolonged or heavy use.

In addition to its high-temperature resistance, Jurid® offers also an excellent wear resistance. The metal fibres used in the brake block provide extra strength and durability, ensuring that the brake blocks have a long lifespan and require minimal maintenance. The combination of high-temperature resistance and wear resistance makes Jurid® a highly reliable and cost-effective choice for railway operators.

Jurid® blocks are designed to produce minimal noise and dust. The synthetic resins and ceramic materials used in the brake block reduce the amount of noise generated when the brake blocks come into contact with the wheels, making for a quieter and more comfortable ride. The low dust production also ensures that the brake blocks are environmentally friendly and do not cause any health hazards to passengers or staff.

Another benefit of Jurid® is its ease of installation. The brake blocks are designed to fit seamlessly into existing railway systems, making them a straightforward and efficient upgrade option. This ease of installation ensures that railway operators can upgrade their systems quickly and with minimal disruption.

Function of railway brake blocks

Railway brake blocks are used to slow down or stop the train by creating friction between the wheel and the track. When the train driver applies the brakes, the brake blocks press against the surface of the wheels, causing them to slow down or stop. The friction between the wheel and the brake block is what slows down the train, so the quality of the brake blocks is critical for the safety of the train and its passengers.

Maintenance of railway brake blocks

Regular maintenance of railway brake blocks is essential for their safe and efficient operation. The maintenance schedule for brake blocks varies depending on the type of brake block, the railway system, and the usage of the trains. However, some general maintenance guidelines include:

- Regular inspection of the brake blocks for wear and tear.

- Replacement of worn or damaged brake blocks.

- Lubrication of the brake blocks to reduce noise and wear.

- Regular cleaning of the brake blocks to remove dust and debris.

Replacement of railway brake blocks

The replacement of railway brake blocks is an essential maintenance procedure to ensure the continued safe and reliable operation of trains. Over time, brake blocks wear out due to the friction and heat generated during braking. When the brake blocks reach their minimum thickness or show signs of excessive wear, they need to be replaced promptly.

After the replacement, the brake system is thoroughly tested to ensure its effectiveness and compliance with safety regulations. This testing may include simulated braking scenarios and performance assessments to verify the proper functioning of the new brake blocks.

Regular replacement of railway brake blocks is crucial to maintain optimal braking performance, reduce the risk of accidents, and extend the lifespan of the brake system.

Contact us to order your brake blocks on time, so the train is as short as possible out of can be in service as fast as possible.

Contact us about Jurid® brake blocks

Do you need any information about Jurid® brake blocks?

Contact our Friction Specialist Dave Habets by phone at +31 – 10 3134 720 or send an email.

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.