Friction Solutions

Grip in demanding circumstances

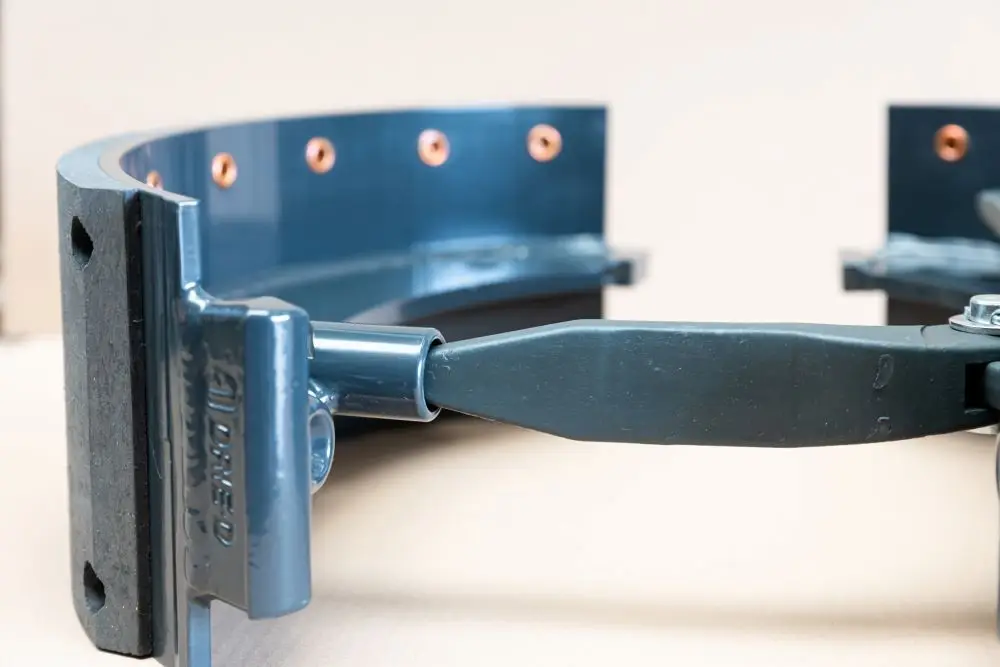

Friction technology has many meanings. In the context of DRIE-D it means working with and application of friction materials to control mechanical motion. Supplying brake lining, friction discs, clutch facings and other components made with friction material has its own challenges. Engineering, solving problems and processing the materials in our modern, well equipped work shop, resulting in delivery of the products to end users.

The scope of supply comprises of a range of materials, all initially designed to turn kinetic energy into heat, applied in specific and custom products. With their properties, the materials can also excellently be utilized in for instance gripper systems designed to gently but very firmly hold things. In the range of materials, some are very rigid, some flexible, some are moulded, some are based on a woven cloth, some contain large quantities of metals for optimum conductivity, some are metal free to be as gentle as possible for the counter face, some can be used in water or even in oil, some need to remain dry, some are ultra-modern based on materials such as Kevlar. For each of the materials we perfectly know and understand how to use and apply them and what their performance in use will be.

Certified friction materials

The supply of certified friction materials for the Maritime Industry is one of our specialties. We supply all kind of friction materials, such as brake lining certified by Bureau Veritas.

A special category within our friction technology consists of railway products. DRIE-D is the Dutch importer of the Jurid/Federal-Mogul range of railway brake blocks and brake shoes, as well the distributor of these items to railway operators and maintenance companies throughout Europe.

Control your movement

Our dedicated engineers work in teams to create the best possible solution. Pure specialists thriving on the challenges of modern world engineering. We can design and engineer solutions for your specific friction challenge.

We produce friction material based components. Brake linings based components like wear bands used on winches, clamping devices and handling systems used on ships. But we also produce brake shoes, custom brake discs and brake blocks which are used on trains and wagons.,

Due to our design and production capabilities, we can supply components customized for any type of equipment and fit for the purpose required.

Sustainable & innovation

At DRIE-D we preferably work with friction materials manufactured with Western technology. Made with care and attention for the environment, asbestos free and following the highest quality standards. Our ongoing strive for quality is substantiated by our friction materials being tested by independent test organizations and our unique brake lining being certified by Bureau Veritas.

Our profound knowledge and experience of working with friction materials, creates opportunities for an innovative approach and even to manipulate the material in perfect geometry. We are not just a reliable supplier of the material, we make use of its properties in the best way it suits your project. That approach allows us to make custom brake solutions for any type of friction challenge.

Quality assurance & project management

High standards are pursued in our projects and products, relying on quality material and careful production.

The quality of our materials is ensured by a certified manufacturing process. Our skilled craftsmen are specialized in working with friction materials and their accompanying handling processes and procedures.

All products that enter our company are inspected, tested and dimensionally controlled. Inspection by third parties is common practice (LR/DNV/BV, etc.).

Project management secures pursue of quality and milestone planning for more complex products or during involvement in large scale projects. Our people are well trained and experienced in project management and project engineering with supporting control in place like ITP, PIP, PEP, Progress reports, MDB and FAT tests.

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.