Your trusted partner in inventive bearing technology

Custom-made

Serial production

Engineering

Test facility

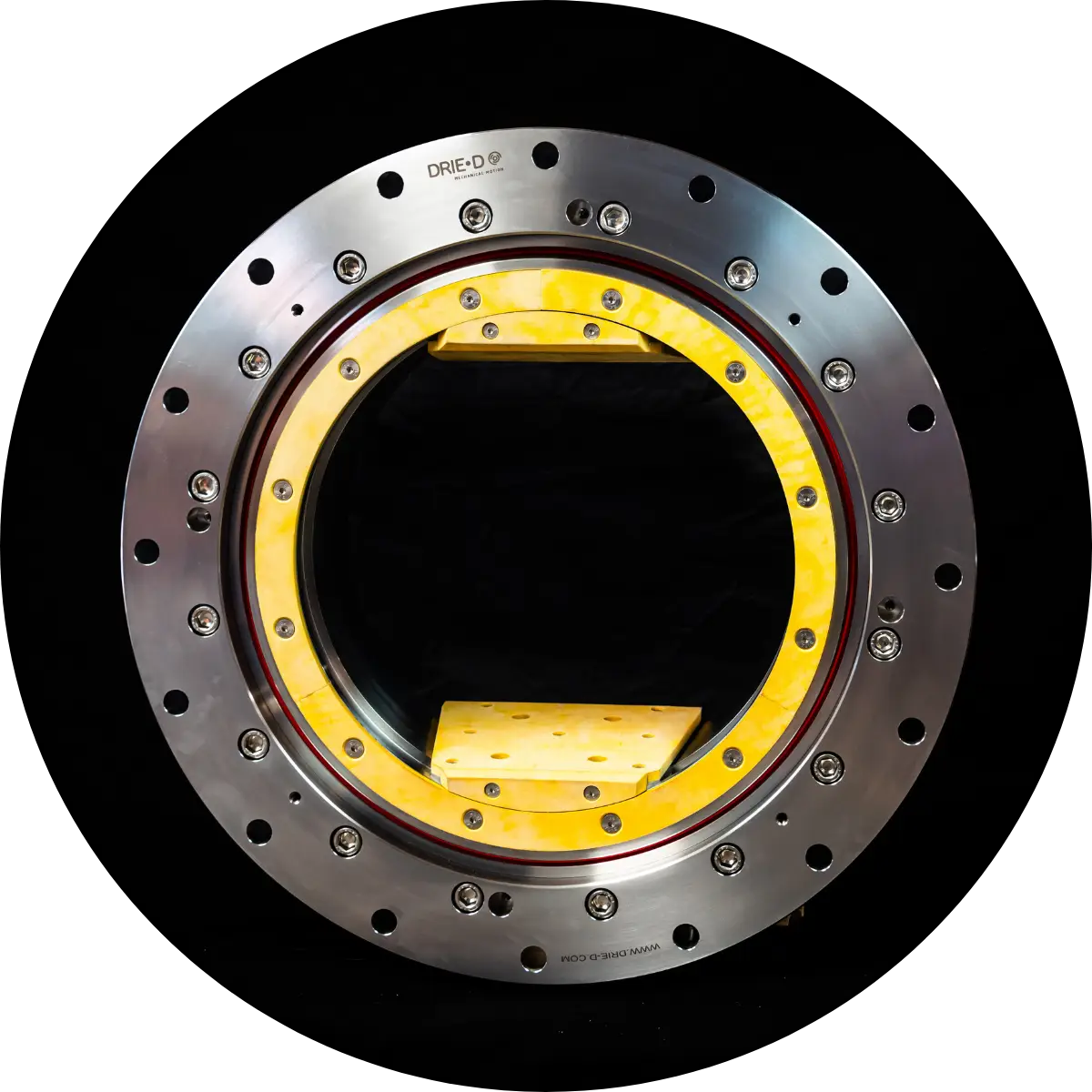

D-glide® composite bearing material

Our specially developed durable self-lubricating D-glide® composite bearing material (often called FRP/FRLP) offers additional technical opportunities compared to traditional (metallic) bearings.

D-glide® is a composite bearing material made from the latest generation of synthetic fibres, thermoset vinyl ester resin, solid lubricants and additives.

We produce different products out of D-glide® composite bearing material for customers all over the world. Whether it is a large custom-made spherical bearing or serial produced standard parts like bushings or wear pads.

Friction solutions

The application of friction materials to control mechanical motion. Supplying brake lining, friction discs, clutch facings and other components made with friction material has its own challenges. Engineering, solving problems and processing the materials in our modern, well equipped work shop, resulting in delivery of the products to end users.

Who we are

At DRIE-D we are continuously developing inventive self-lubricating bearing solutions for heavily loaded applications in the most demanding environments.

Specialized in mechanical motion, our engineers are committed to design the best possible bearing solution. Our experience and cooperative approach are the binding factor in creating progressive designs together with our customers.

Are you also interested in a new and cooperative approach, to jointly find the best, most durable and reliable bearing solution for your mechanical motion challenge?

Our services

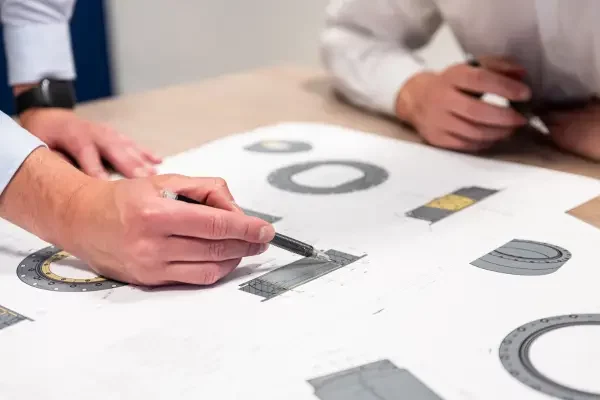

Design & Engineering

Our engineers support you from the very first concept design to the detailed design of the final components in making the right choices to achieve the most sustainable and cost-efficient possible design.

Project Management

Challenging projects and complex bearing solutions require proper management. From initial engineering and design through to production and final installation, our professional multidisciplinary team handles every aspect of the project. We guarantee high-quality results and timely delivery, meeting all our clients' and leading class societies’ requirements.

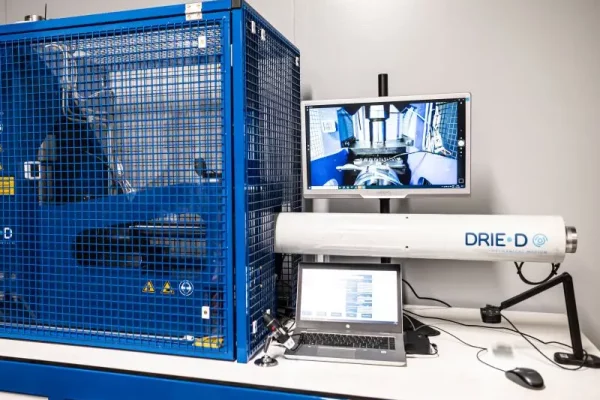

Friction testing of material combinations

The friction behavior of a material combination depends on a large number of variables. With 25 years of practical experience, supported by the results from our own test facility, DRIE-D strives to propose the best possible material combination for every application in order to meet the customer's requirements.

Finite Elements Analysis

Our engineers can validate our bearing design both mathematically and using FEA software. The knowledge of our bearing materials enables us to make detailed FEM analyzes and thus fine-tune the designs in terms of peak stresses and manufacturability.

On-site support

Our trained service engineers are specialized in on-site bonding processes and can also be deployed to supervise the installation of complex bearings. Besides that, we are also available for inspection of existing equipment.

Bonding

Good bonding highly depends on following the correct procedure. Our specialized mechanics have years of experience in correctly bonding D-glide® and friction materials. All work is carried out according to our own developed bonding procedures and in a conditioned environment in order to achieve the best possible connection.

Transport services

The delivery of high-quality products also includes providing a suitable method of transport. Our own transport department delivers our products to your location and provides support with arranging national and international shipments.

Applications

At DRIE-D we like setting new standards for heavy loads or harsh operation, environmental safe and maintenance friendly. Highly specialized in mechanical motion, we provide a smooth solution for your rough challenge! Our engineers are experienced and specialized to design solutions in these fields.

Dredging

Container handling

Renewable energy

Agriculture

Civil engineering

Observation wheels

Offshore

Maritime equipment

Mission equipment

Heavy lifting

Gangways

Rail

Our projects

Heave Chief

Challenge: Ensuring minimal friction during continuous motion under high loads for a balanced heave compensation system.

Hexapod

Challenge: Design a lightweight solution for the limited space that is exceptional adaptable to varying angles and loads.

Hardt Hyperloop

Challenge: Design supports that can handle the variability in material properties, especially in relation to ambient temperature fluctuations.

Afsluitdijk

Challenge: Design and produce D-glide® bearings for the discharge sluices, non-return valves and the innovative fish migration slider.

Our people